MS-15

3D SPIMS-15PREMIUM 3D SPI FOR SMT/SEMI

|

|

|---|

Product Features

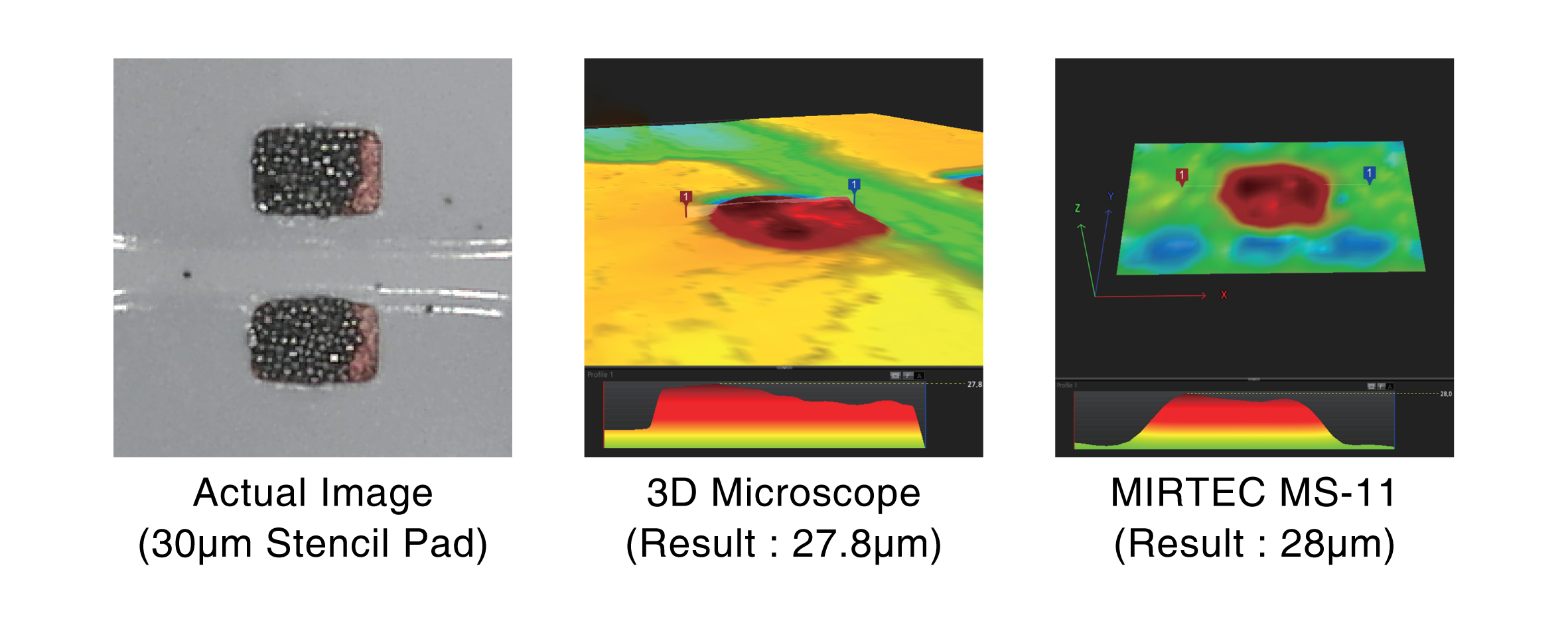

With dramatic improvement of accuracy & repeatability by S/W & H/W renovation, the MS-15 can precisely measure and

MIRTEC has implemented a next-generation vision system featuring 4㎛/6㎛ high-resolution lenses for greater precision and stability in inspection.

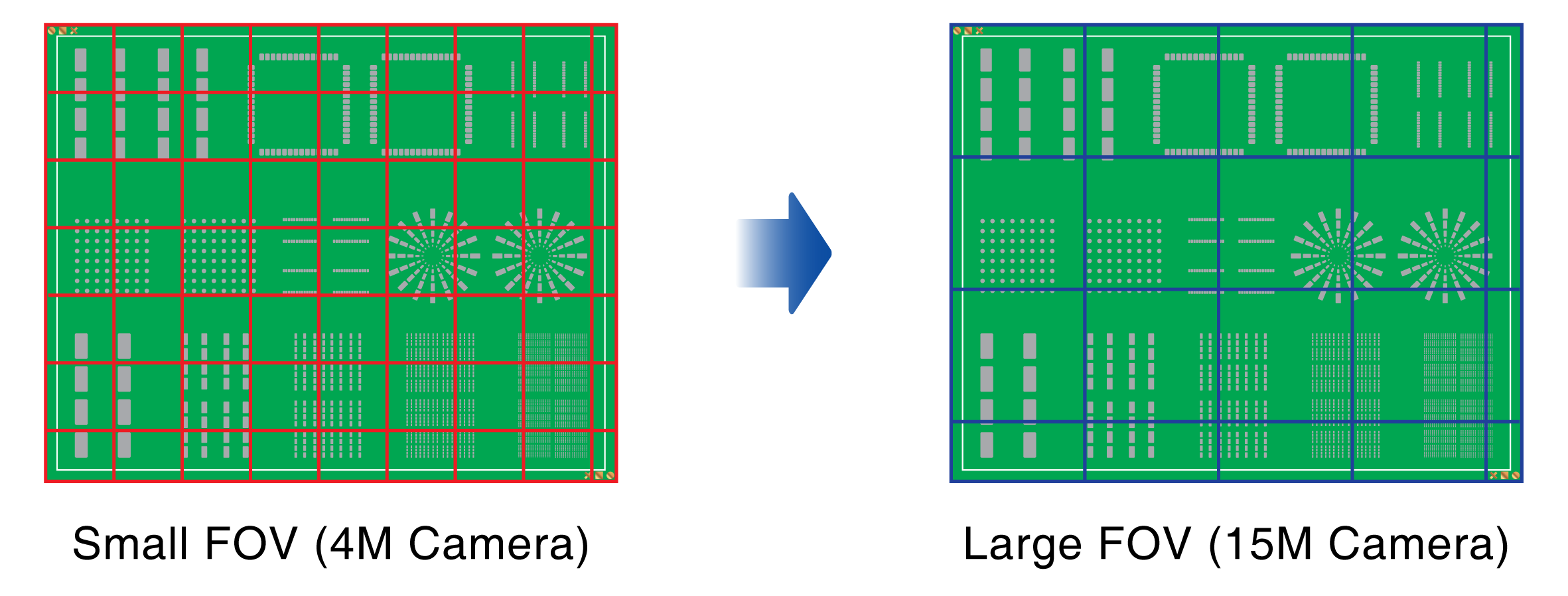

With a large field of view (FOV), a larger and clearer image can be captured in a single shot, reducing the number of images required.

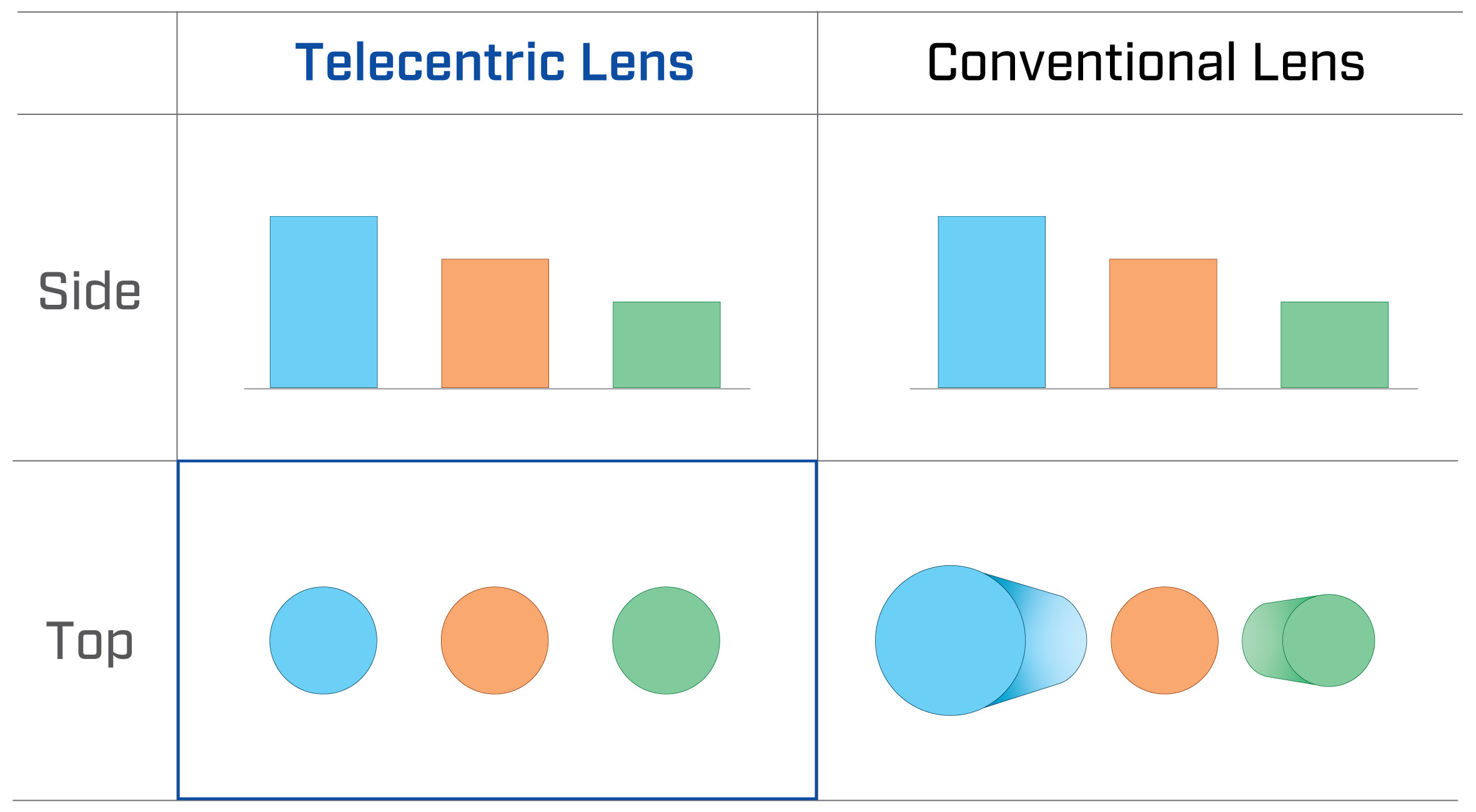

Many 3D SPI systems on the market use conventional lenses, which cause image distortion.

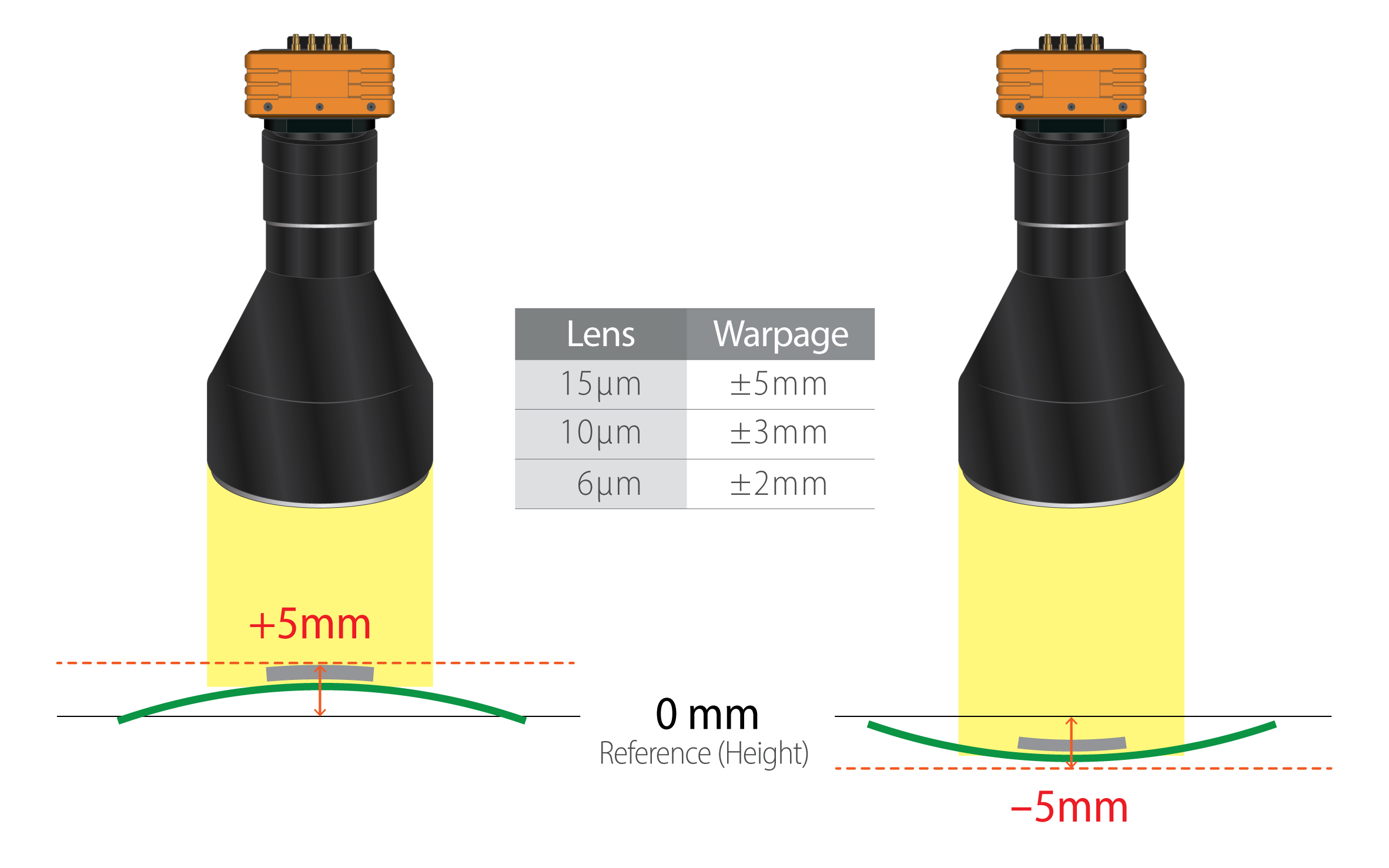

The MS-15 SPI machine detects and automatically compensates for PCB warpage up to 士5mm within its field of view (FOV) using the Z-axis, while capturing the board images.

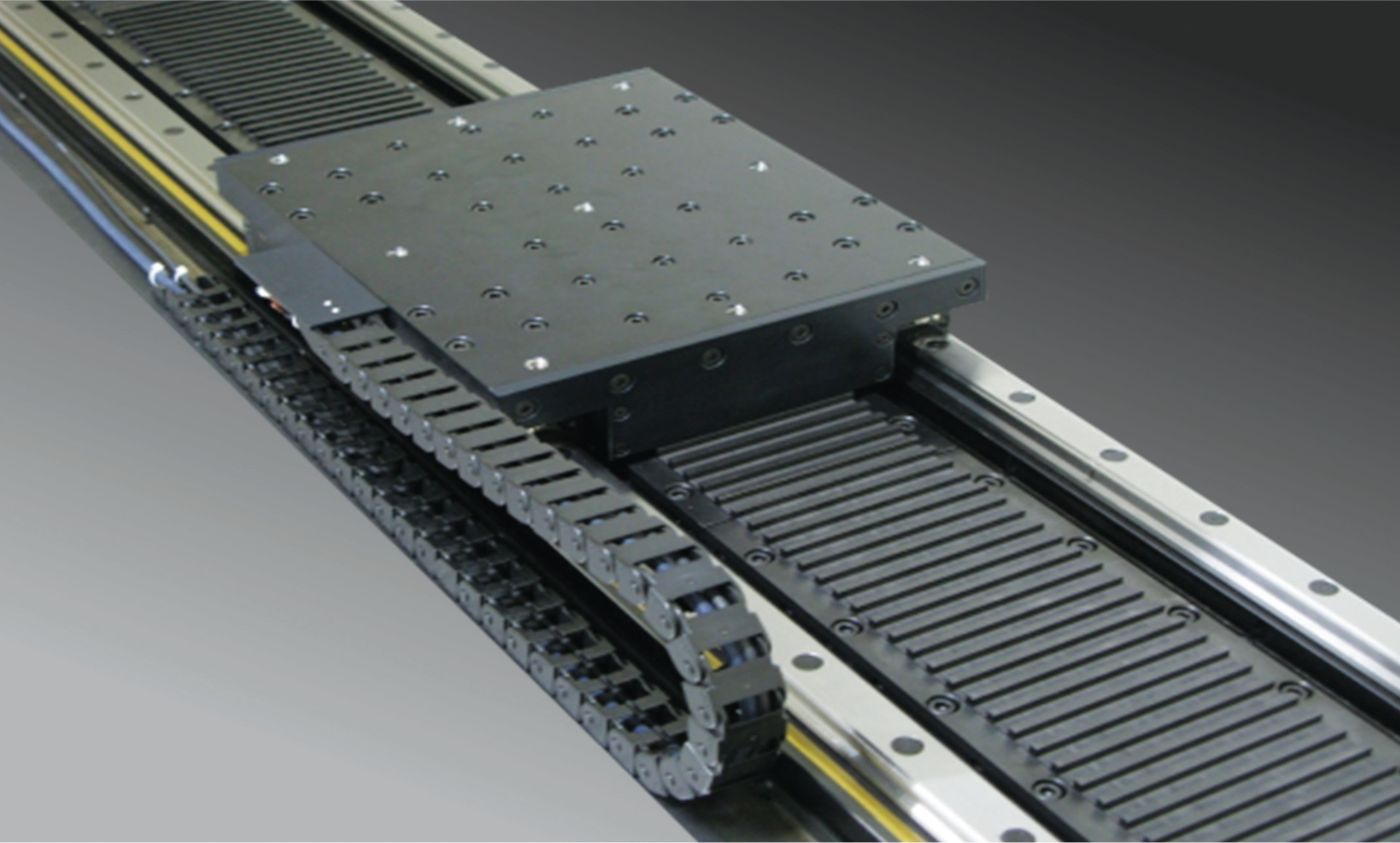

The system is equipped with a dual-drive linear motor, enabling semiconductor-level repeatability in inspection.

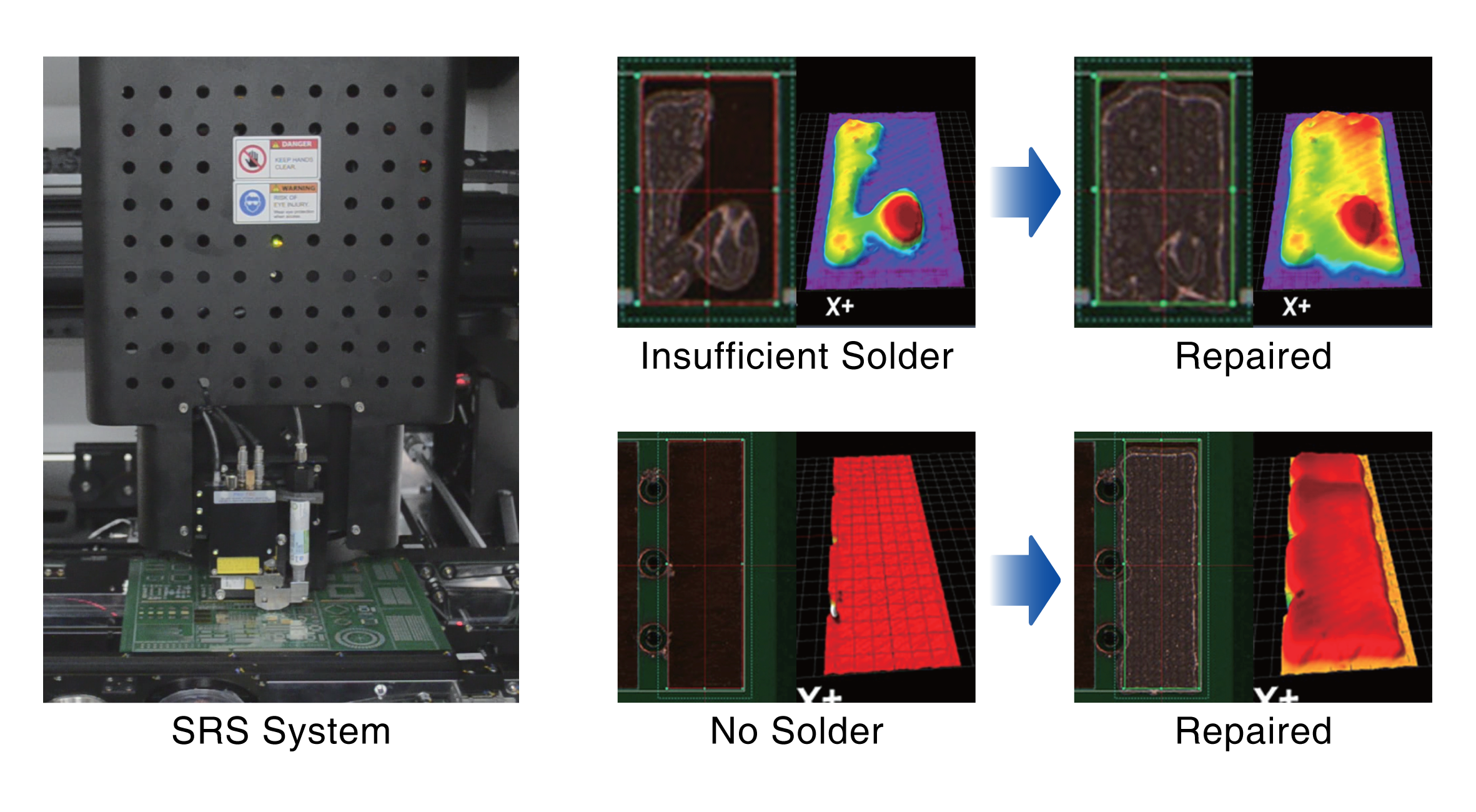

MIRTEC's SSF (Solder Supplying Function) automatically supplies solder onto insufficient or missing pads using a solder dispenser integrated into the optical system after inspection

|

Related Video |

Global Site

Global Site