SPI

The most reliable quality

assurance solution

SPI is a advance guard to the quality management: the most effective means of improving production efficiency in the early stages of production Mirtec's SPI has secured high precision and repeatability by adopting a leading optical technology, superior than other competitors. Based on this advantage, the SPI can be used for general SMT as well as semiconductor productions as the SPI can detect the very minimal amount of solder paste for defectives. In addition, Mirtec's diverse process management sofrware is a very effective way to optimize the process and improve production efficiency by realizing problem on production and statistically analyzing the problem based on M2M communication with SPI.

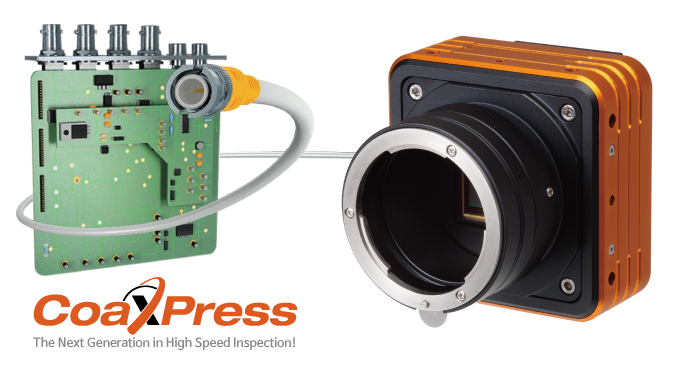

01.

High-speed, High-precision inspection

utilizing high optical specifications.

Using a high resolution camera with a precision lens, Mirtec’s SPI performs stable and precise inspections on lead defects without any issues of lowered speeds. Based on the high precision and repeatability, the device handles the semiconductor post-processes without any speed drops as well. With combinations of camera and lens of various resolution, the inspection solution can be tailored for the production purposes.

02.

3D measurement free from

shadows and reflections

The Shadow-Free Dual Projection Moire Probe eliminates the possibility of distortion due to shadows when 3D measuring a high solder. By combining the pattern images of opposite direction, a perfect 3D measurements is possible and thus is free from reflective shadows.

03.

Bending and Warping Correction Function

The precise height measurement capability of the machine allows to automatically detect and correct bending states of PCB board. Normal inspections can be conducted on even bent or warped PCBs.

04.

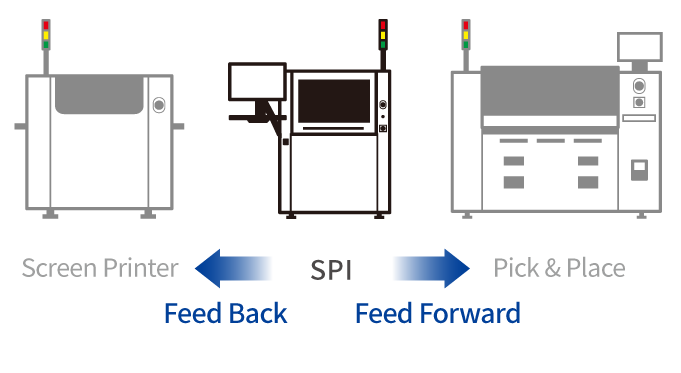

Closed-Loop System

Using real-time data communication from screen printers and mounter, the machine exchanges information like the pad and solder paste location to solve the source of defect and optimizes the process.

USA

USA 日本

日本 中国

中国 Germany

Germany Mexico

Mexico Vietnam

Vietnam