Smart Factory Solutions

The Industry 4.0 Realizing

Solution – Intellisys®

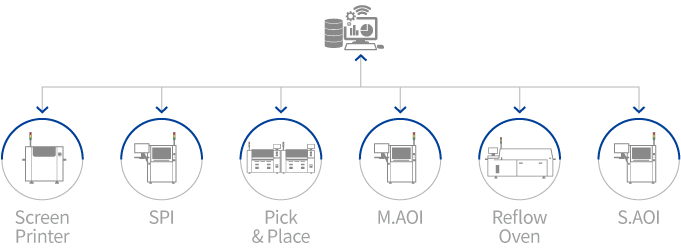

Our software solution, Intellisys®, gathers

the data accumulated over a long period and build

big data and analyzes through statistical methodologies

to track the cause of defectives.

Moreover, the equipment can be managed and

controlled from a remote location, which efficiently improves processes.

Furthermore, Intellisys® is a powerful software

solution that realizes the core of smart factories

using the big data analysis, data communication among multiple devices,

remote monitoring and control, and machine learning.

01.

Statistical process management

based on big data

Big data is one of the core element of Industry 4.0 We have constructed big data using the SPC Server

to collect the accumulated large-scale inspection data and images from multiple production lines.

Then, using statistical analysis performed by a high-performance server system, we were able to derive

the correct conclusion for the production process optimization.

TLM(Total Library Manager) provides optimal inspection an optimized inspection parameters based on data,

and analyzes the logs to improve the inspection results.

02.

Tracking the cause of defect

Intelli-Track is a process management system that tracks the cause defectives through the inspection data and images stored in SPI, AOI, AXI. Also, the solution analyzes the yield rate and defect types, and provides various processed information such as detailed information of defect and improvement plan for the for process improvement.

03.

Connectivity and Remote Management

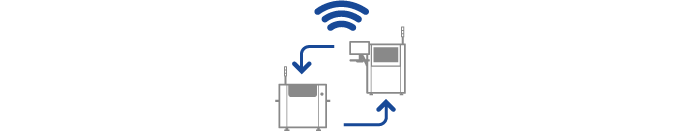

USING TRMS(Total Remote Management System),

all equipment from multiple production lines are

monitored and controlled by a single computer at a remote location.

Any production equipment connected to the network can be monitored and controlled.

The factory can be efficiently operated because the production lines can be

managed and controlled by minimum number of management personnel.

04.

User Convenience

Mirtec's AOI realizes high-speed and high-precision inspection through high resolution camera’s wide FOV, CoaXpress high speed image transmission standard, and data processing using server grade computer. Moreover, the linear drive motor system is adopted as a powertrain, which can secure the repeatability required for the post-process for semiconductors.

USA

USA 日本

日本 中国

中国 Germany

Germany Mexico

Mexico Vietnam

Vietnam