MV-9SIP

SEMI 3D AVIMV-9SIPPREMIUM 3D AVI FOR SEMI POST-PROCESSING

|

Product FeaturesHybrid 3D SiP Inspection Technology

SiP (System in Package) consists of bonded components with varying characteristics, requiring a combination of multiple inspection techniques for optimal results.

12 Projection Digital Blue Light MoiréMIRTEC's patented 12-Projection Digital Blue Light Moiré technology enables precise and stable 3D inspection, unaffected by the color of the part or substrate. This technology is especially effective for inspecting small, high-density components and maintains measurement accuracy even on curved surfaces, such as solder fillets.

Hybrid Laser Scanning

Objects with highly reflective or extremely low-reflective surfaces are challenging to inspect using conventional optical methods, but MIRTEC overcomes this limitation.

25M 7.7㎛ High Resolution Camera

MIRTEC has implemented a next-generation vision system featuring 7.7㎛ high-resolution lenses for greater precision and stability in inspection.

8-Phase Coaxial Color Light

All of MIRTEC's 3D AVIs come standard with Coaxial Lighting, which is highly effective for inspecting CSP parts, a significant portion of SiP inspection targets.

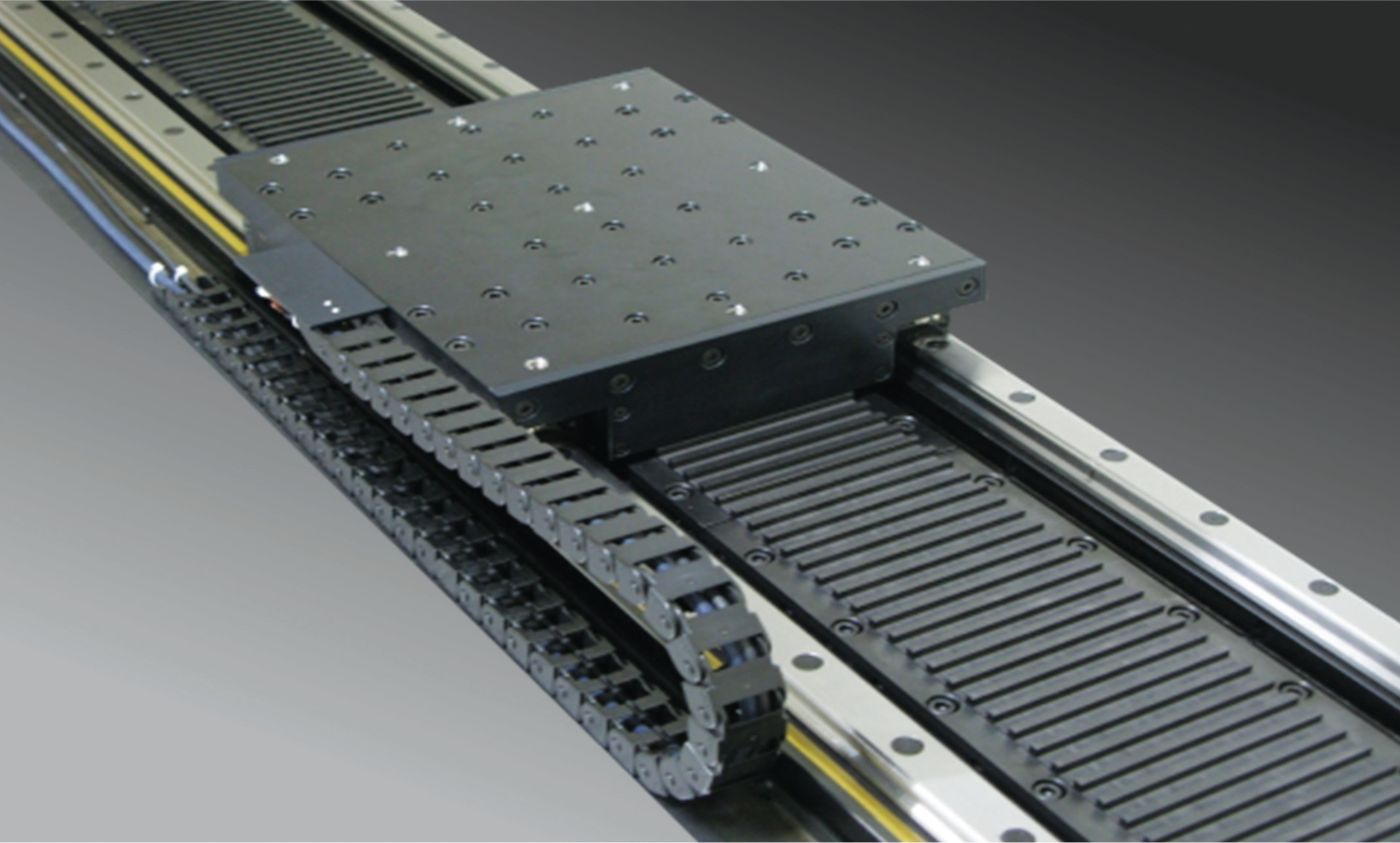

Dual Drive Linear MotorThe system is equipped with a dual-drive linear motor, enabling semiconductor-level repeatability in inspection.

|

Related Video |

USA

USA 日本

日本 中国

中国 Germany

Germany Mexico

Mexico Vietnam

Vietnam